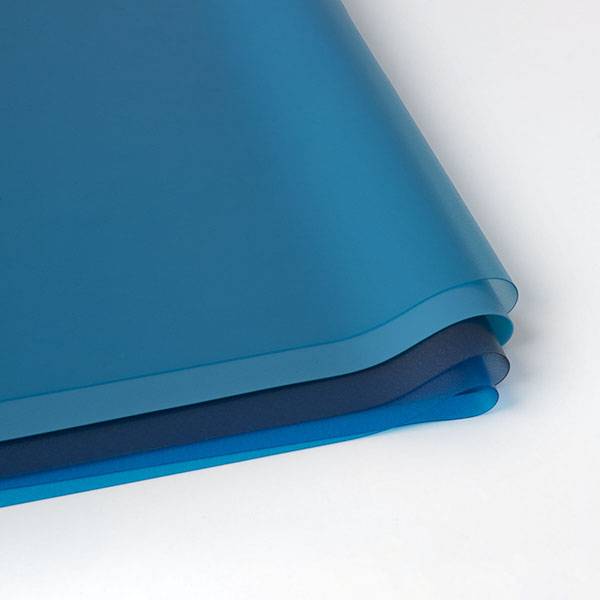

Free sample for Pvb Film Recycling - Light blue B113 / Opaque light blue B102 / Ford blue B118 / Ocean blue B105 – Baizan

Free sample for Pvb Film Recycling - Light blue B113 / Opaque light blue B102 / Ford blue B118 / Ocean blue B105 – Baizan Detail:

Use Process

Baizan color pvb film for architecture glass

Productivity>12000t per year

Color pvb MOQ>5000 sq.m.

Payment term:TT LC DP

Delivery:5-10days

After-sale service:We will follow customer’s testing result, and if there is a problem, we will check it out at site.

Glass Cutting Glass Cleaning and PVB Film Cutting

● Properly cut the glass at precise size

● Check glass surface and remove grease and dusts, clean the glass by tap water.

● Rinse the glass by demineralized water/Softened water. Water quality<30μS, water hardness<10 PPM, temperature is 40~60℃.

● Air dry the glass and keep it away from pollution.

● PVB film should be cut at size of bigger than 2~5mm extra than glass size.

Lamination

● Lamination room — The temperature in lamination room should be 20~25℃,the humidity should be 23%±2%,dusts proof, keep the machinery tidy, workers should keep the tidy uniform, hat and grove to prevent PVB film from dusts, contaminates and hair.

● Lamination conditions:

a)The glass surface temperature—20~30℃, the upmost should not over 40℃.

b)The PVB film temperature—20~25℃.

c)Check again the PVB film and glass is tidy and the glass size properly match the PVB film size.

Pre-Pressure Exhaustion

Cold vacuum and hot vacuum

a)Cold vacuum — Compression vacuum degree should be at 580~680mmHg, temperature at 20~25℃, pressure at -0.095~-0.1MPa. It takes around 20 minutes in Continuously Cool Pumping, while 30 minutes in Un-continuously Cool Pumping.

b)hot vacuum — The glass surface temperature should be at 100~120℃, it takes 30~45 minutes, pressure should be at -0.095~-0.1MPa. The glass can be taken out when the temperature decreases to 60~80℃.

● Rolling Exhaust:

a)First thermostat —→ The heated Laminated Glass surface temperature is 30~40℃ —→ First roller, pressure is 5~8Mpa, the roller distance should be 1-2mm less than Laminated glass thickness —→ Second thermostat —→ the laminated glass surface temperature is 65~80℃, the pressure is 5~8Mpa, the roller distance is 2-3mm less than laminated glass thickness.

b)Keep the thermostat temperature by continuous work.

High Pressure Formation

The temperature and pressure rising is at low speed during whole procedure. The procedure below for reference:

Raise temperature and pressure—→Temperature rise to 60℃, Pressure to 0.4MPa—→Pressure to 0.8MPa,temperature to 90℃—→Pressure to 1.0MPa,, Temperature to 135-140℃—→Rise the temperature to 1.05~1.28MPa—→Keep the temperature 30~60 minutes(depend on the glass thickness and quantity)—→Keep the pressure, freely decreasing the temperature to 90℃—→Temperature decrease to 45~55℃, release the air

Customer usage scenarios

Product detail pictures:

Related Product Guide:

Innovation, excellent and reliability are the core values of our firm. These principles today more than ever form the basis of our success as an internationally active mid-size corporation for Free sample for Pvb Film Recycling - Light blue B113 / Opaque light blue B102 / Ford blue B118 / Ocean blue B105 – Baizan , The product will supply to all over the world, such as: El Salvador, Estonia, Myanmar, Insisting on the high quality generation line management and customers expert assistance, we now have designed our resolution to offer our buyers using the to start with amount getting and just after services practical experience. Maintaining the prevailing friendly relations with our buyers, we however innovate our solution lists all of the time to satisfy the brand new demands and adhere to the most up-to-date development of the market in Malta. We are ready to face the worries and make the improve to understand all the possibilities in international trade.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!