Good Quality N-UV lonoplast pvb – N-UV PVB – Baizan

Good Quality N-UV lonoplast pvb – N-UV PVB – Baizan Detail:

N-UV PVB

N-UV pvb film is a new interlayer technology for durable architectural safety glass with unsurpassed transmission of natural UV light into spaces appling to special light-requiring flora and fauna

Drop ball impact peel performance

Prepare 6 pieces of 300*300mm glass with 2mm thickness and put them flat, then put the sample on , and then cut it, pay attention to avoid stretching to prevent deformation, and to ensure that the membrane margin outside the glass is about 2mm. Then, the finished mesofilm glass was put into a 160±5℃ vacuum chamber for vacuuming and kept for 90 minutes under a negative pressure of 8.5×104Pa.

Put these 6 samples at a temperature close to 20 + 5℃ for at least 4 hours, respectively, will close on fixed glass bracket of impact test, then the weight is 1040 g + 10 g, steel ball according to the height of about 63.5 mm in diameter from 1200 mm and 1500 mm, 1900 mm and 2400 mm, 3000 mm and 3800 mm in the order hoisting height vertical shock, impact point should be located in the heart of the sample, 25 mm range, the status of each shock after the destruction of the glass

Knock test

Prepare 2 pieces of 76*300mm white glass with thickness of 2mm .Lay the glass flat, put a layer of sample and then a layer of glass, finally cut it down. Pay attention to avoid stretching the film to prevent deformation during cutting, and ensure that the diaphragm margin outside the glass is about 2mm.The finished mesofilm glass was put into a vacuum chamber at 180±5℃ for vacuuming, and kept under a negative pressure of 8.5×104Pa for 30 minutes before being removed.Cool the sheets for half an hour and then place them in an environment of -18℃ (±1℃) for 2 hours. Then remove them and immediately start tapping with a flat hammer from the bottom of the glass

The striking area should exceed at least 1/2 of the glass, then visually observe the degree of falling off of the glass in the striking area, and estimate the percentage of falling off area to determine the corresponding level

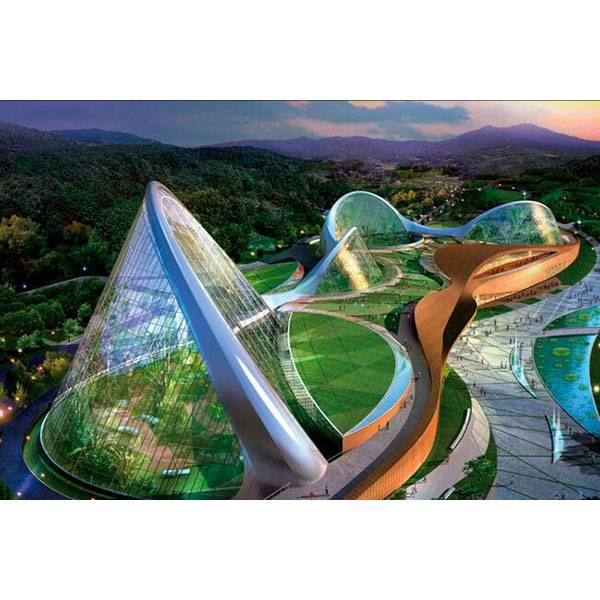

Product detail pictures:

Related Product Guide:

No matter new customer or previous client, We believe in prolonged time period and trustworthy relationship for Good Quality N-UV lonoplast pvb – N-UV PVB – Baizan , The product will supply to all over the world, such as: Argentina, Pakistan, Atlanta, The best and original quality for spare parts is a most important factor for transportation. We may stick on supplying original and good quality parts even a little profit earned. God will bless us to do kindness business forever.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.