OEM Manufacturer Pvb Interlayer Laminated Glass - Medium brown BK104 / Medium brown BK103 – Baizan

OEM Manufacturer Pvb Interlayer Laminated Glass - Medium brown BK104 / Medium brown BK103 – Baizan Detail:

Medium Brown Pvb

Baizan color pvb film for architectural laminated glass.

Baizan can provides plenty of color film for customers choose with stable and accurate color.

production volume >12000t per year

Color pvb MOQ>5000 sq.m.

Payment term:TT LC DP

Delivery time :5-15days

After-sale service:We will follow customer’s testing result, and if there is a problem, we will check it out at site.

Raw material inspection

In order to ensure the quality of products, we carry out strict inspection on raw materials, according to China national standards。

Detection of PVB resin powder

| project | volatile | viscosity(20℃ 10%/S) | Packing density(g/㎝3) | Melt index(120℃ 21.6kg g/10min) | The fog degree(%) | Light transmittance(%) | Acid value(mgKOH/g) | The hydroxyl content(Wt%) | Butyl group content(Wt%) | transparency |

1.Sampling: after every lot of raw material arrive at factory, about 5kg samples will be taken from each lot.

2.Appearance test: white, fine and even, free from any impurity, free- flowing powder or particle.

3.Whiteness: take 2kg of the sample, add 1kg of plasticizer, mix well, extrude and shape the membrane, compare the color

4.The volatility:Weigh up the sample with an analytical balance and place it in a weighing bottle. Keep the bottle in the oven for 3 hours, with temperature 60℃(±1℃) . After taking it out, place it in the dryer for 20-30 minutes and then weigh it.

5.Viscosity:Add resin powder into a paper funnel, put a condensing tube in the 65℃ water bath for 1h, and when it is taken out and cooled to a constant temperature of 20℃±1, pour the sample into a scale cup, and record the time the first drop of solution reach to 50ml, which is the viscosity of the sample

6.Melt index:Weigh the powder and the plasticizer (1:3), adding the plasticizer first and the powder later. After adding it into the melting index flow rate meter, preheat for 4 minutes, add 21.6g weight and start extruding. After 3 minutes, cut off the first section, and then wait for 5 minutes before cutting the second section. The total weight of two sections will be the melting index value.

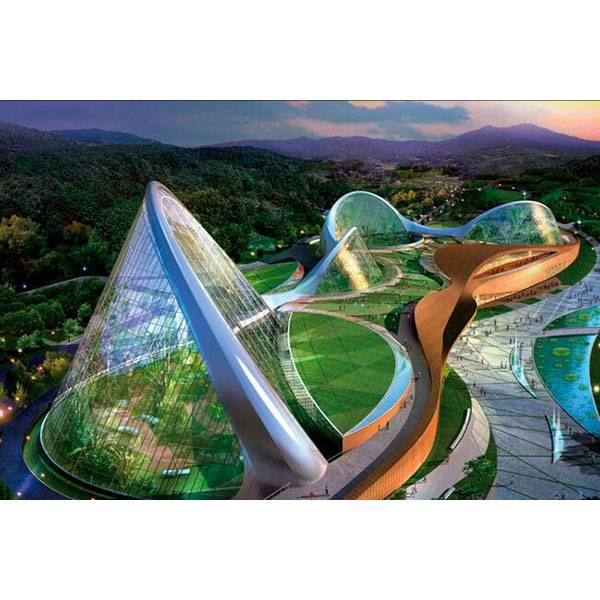

Customer usage scenarios

Product detail pictures:

Related Product Guide:

With our loaded encounter and considerate services, we have now been recognized as a trustworthy supplier for lots of worldwide consumers for OEM Manufacturer Pvb Interlayer Laminated Glass - Medium brown BK104 / Medium brown BK103 – Baizan , The product will supply to all over the world, such as: Romania, Rotterdam, Croatia, We have more than 10 years exported experience and our products have expored more than 30 countries around the word . We always hold the service tenet Client first,Quality first in our mind,and are strict with product quality. Welcome your visiting!

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.