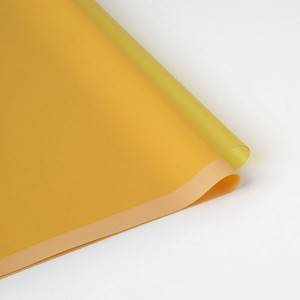

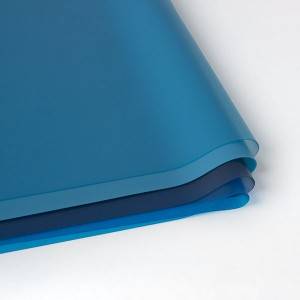

Yellow Y101 / Opaque yellow Y102

Yellow Pvb

Baizan color pvb film for architectural laminated glass.

Baizan can provides plenty of color film for customers choose with stable and accurate color.

production volume >12000t per year

Color pvb MOQ>5000 sq.m.

Payment term:TT LC DP

Delivery time : 5-15days

After-sale service:We will follow customer’s testing result, and if there is a problem, we will check it out at site.

Baizan PVB interlayer is a macromolecule material molded by polyviny, butyral resin that is plasticized and extruded by plasticity. Our PVB film with excellent light transparency, heat and cold resistance, elasticity, is well-sticking to inorganic glass and the making of laminated safety glass. Usual thickness specification is between 0.2 mm - 2 mm.

Baizan PVB interlayer is mainly used in making laminated safety glass. Laminated glass is a special glass which is inserted with PVB film between two layers of common glass, which under high heating temperature and pressure, binds to create a single construction. Because of PVB laminated glass with the function of safety, heat preservation, noise proof, and

Raw material inspection

Detection of PVB resin powder

1.Determination of transparency and fog

Operation tips: First, clean the surface of the glass with ethanol to ensure that the glass is clean. Place a PMMA glass mold on the glass sample, add resin powder into the square groove and smooth with a glass rod, take out the mold, cover another piece of glass, and transfer to the vulcanizing machine for hot pressing. Firstly, prepress at 0MPa and 125℃ for 3~4 minutes, and then compacting at 0.25MPa, which takes 5~6 minutes, namely hot pressing is completed. The thickness of single piece of glass and the total thickness of laminated glass were measured with vernier caliper, the thickness of laminated glass was estimated (about 0.76mm), the haze of four orientation points of laminated glass was measured and averaged, and the thickness of laminated glass was divided to get the parameter value. At the same time, a piece of insulating glass or laminated glass should be prepared as the blank control group to offset the instrument error.

2.Butyl content

Operation Tips: Dissolve the resin powder in the anhydrous ethanol solvent first, then add hydroxylamine hydrochloride solution, stir evenly and then heat reflux in the thermostatic water bath for 2.5h to make the solution in the conical flask clear and transparent. From the top of the condensing tube, add 50ml water for cleaning, take out the conical flask and cool to room temperature, then add 3~4 drops of 0.1% bromophenol blue indicator, titrate to neutral with the calibrated 0.1mol/L NaOH solution, compare with the blank group, and correct to calculate the butyl content.